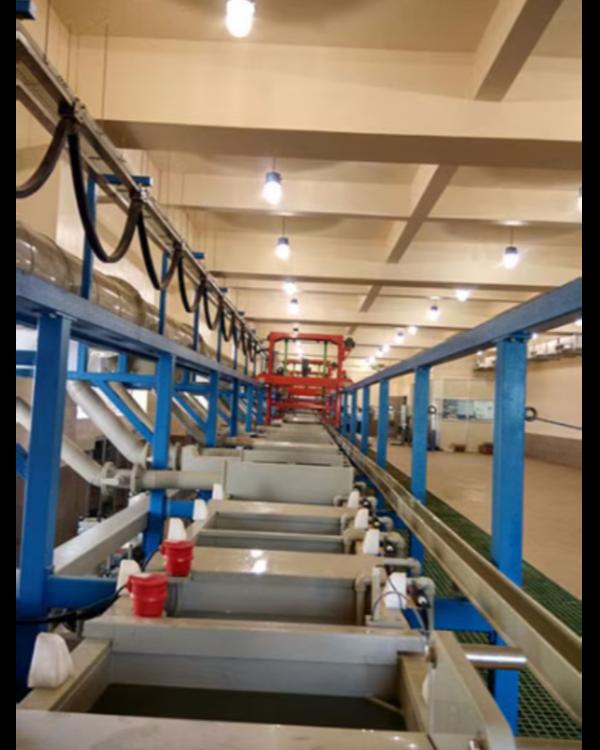

A well-designed nickel plating line in Bangalore is essential for manufacturers looking to improve corrosion resistance, wear protection, and visual appeal of metal components. Nickel plating is widely used across automotive, electrical, and engineering industries because it enhances both functional strength and surface consistency.

Modern nickel plating lines focus on controlled deposition, ensuring uniform coating thickness even on complex geometries. Automated handling between stages reduces manual errors and improves repeatability across batches. Stable bath chemistry, accurate current control, and proper filtration help maintain consistent output while extending bath life.

Operational safety and environmental responsibility are equally important. Effective ventilation systems manage fumes generated during the nickel plating process, while wastewater treatment systems handle chemical discharge in line with regulatory norms. These integrated controls allow manufacturers to run plating operations smoothly without compromising worker safety or compliance.

AK Automation Systems in Bangalore provides nickel plating line solutions tailored to industrial production needs, balancing performance, safety, and efficiency.

Contact us to learn how a professionally engineered nickel plating line can enhance product quality and operational reliability.